Product makers in home chemicals, cosmetics, medicines, and the food and beverage industry are becoming increasingly crucial in addressing customers’ evolving demands and ideals. They must ensure that their items reach their customers in perfect shape. Poor merchandise conditions, such as leaky and broken containers, rotten and contaminated items, are serious issues that endanger safety.

The capacity to achieve a flawless seal every time is now possible thanks to global application expertise and the most sophisticated production procedures.

When used correctly, the induction sealing system may increase the value of a product. Making the container airtight (hermetic) creates a tamper-proof seal that solves all of the difficulties outlined above while retaining an overall professional appearance. The induction cap sealing technology is also great for extending product shelf life and maintaining freshness, which increases consumer confidence.

What to look for in an Induction Seal:

- Within minutes after starting the induction sealing process, a satisfactory seal is achieved. For complete sealing – induction foil, manufacturers strongly advise waiting 24 hours for the optimum final result.

- Heat Excess:Keep an eye out for any symptoms of burning or melting within the cap.

- Underrated – If the foil sealing layer did not melt and connect with the entire rim of the bottle or jar top neck surface.

- Proper heating:It is determined by whether the foil completely seals around the rim of the product and secondary cap lining materials, as well as if the bottleneck and cap are not overheated.

- An experienced operator will understand how hot a bottle lid should be before it begins to cool.

- A trained eye may see symmetric heat patterns in induction foil and foam backing material underneath some induction foils.

Proper Induction Sealing is met if:

- Without the cap, the seal on non-breakable containers can generally withstand the force of a drop.

- The seal on easy-peel seals may be removed without leaving a foil ring behind. The foil must be clipped for permanent weld sealing.

- There was no leak after being dropped.

How to achieve a perfect induction Seal?

The container, cap closure, liner material, and induction seal should all be perfectly matched to achieve a consistent product seal. We propose that you check your cap closure with the Induction Cap Sealing Machine supplier to discover the best combination.

Container

Most induction sealed containers are made of plastic, although glass vessels may also be induction sealed. Induction seals are often used for dry items such as coffee. The container type is selected depending on product suitability, marketing, and logistical concerns.

Cap Closure

To accommodate an induction liner, the cap closure must have a flat interior region. Screw-on caps provide for a broader selection of hard and soft cap liner materials. Snap-on caps are best suited to softer cap lining materials. When employing a two-part induction sealing material in which a foil separates from a backing material, the cap may need to incorporate features that maintain the backing material when the container is opened.

Lining Materials

The following factors influence the selection of an acceptable induction seal material:

- The container Composition.

- The product contents

- The duration of use

- Any Type of Cap Tolerance (e.g., Screw-on or Snap-on caps)

- The procedure for inserting the lining material into the cap

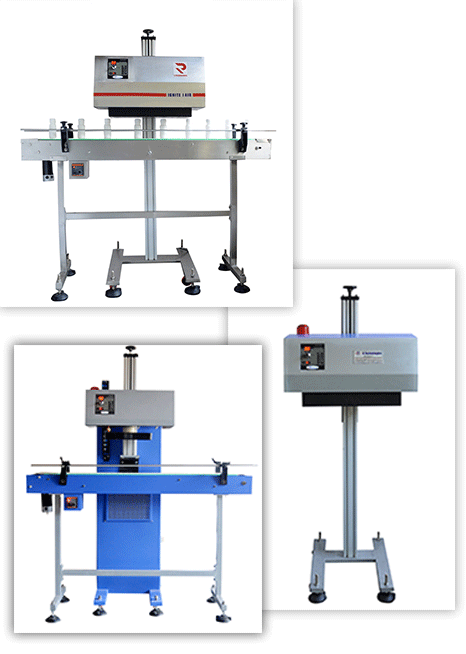

Induction Sealer

Choosing the best machine for your needs is a critical process. When selecting a provider, make sure that they:

- The provider can provide technical guidance on the induction sealing method and, if needed, engage in the closure and container development process.

- The machinery provider either supplies or can advise on the delivery of the induction lining material.

- The provider provides ONLY ISO safety-certified equipment. High electric currents and electromagnetic fields are used in induction sealing equipment. R Induction Technologies Pvt Ltd, for example, is creating and offering very low-cost solutions WITH ISO certification.